General Information:

The wind energy industry faces a constant state of evolution because of challenges such as the pressure to be competitive with other types of energy production and the growing need to reduce operating and maintenance costs. Condition monitoring offers you a way to reduce the cost of ownership for these critical machines by predicting failures before they occur, which helps you effectively schedule proper maintenance.

Vibration monitoring is one of the most important aspects in wind turbine monitoring because it helps to determine the condition of equipment. Wind turbine consists of turbine rotor, stator, bearings, gearbox and generator which all need the corresponding sophisticated signal processing and analysis. VC4000 protection and condition monitoring system has been developed for wind turbines and will be described in the following.

The wind energy industry faces a constant state of evolution because of challenges such as the pressure to be competitive with other types of energy production and the growing need to reduce operating and maintenance costs. Condition monitoring offers you a way to reduce the cost of ownership for these critical machines by predicting failures before they occur, which helps you effectively schedule proper maintenance.

Vibration monitoring is one of the most important aspects in wind turbine monitoring because it helps to determine the condition of equipment. Wind turbine consists of turbine rotor, stator, bearings, gearbox and generator which all need the corresponding sophisticated signal processing and analysis. VC4000 protection and condition monitoring system has been developed for wind turbines and will be described in the following.

Vibsens Wind Turbine monitoring service provides:

-Online data measurement & record

-Vibration trend monitoring

-Detection of spectrum abnormalities

-Establishing base-line operating norms

-Management of alarms and communicating to plant supervisory

-Delivery of scheduled performance reports

Technical advantages:

-Permanent protection of wind turbines

-Detailed diagnosis of rotor, gearbox, generator and other parts

-Root cause analysis by documenting damage events

-Trend recording

-Spectrum recorder

-Different condition monitoring approaches used across the industry, including monitoring equipment and data analysis techniques

-Software developed with CM technologies best suited for your application

-Component level detail, including drive train, vibration monitoring

-Increasing the life of wind turbines through wind turbine CM techniques

-Using maintenance planning to reduce unscheduled maintenance and get more value from your assets through subsequent drops in downtime

-Methods for early indication of component failure and how repair work can be adapted depending on the failure

-Management of several turbines in a wind farm in

-Online data measurement & record

-Vibration trend monitoring

-Detection of spectrum abnormalities

-Establishing base-line operating norms

-Management of alarms and communicating to plant supervisory

-Delivery of scheduled performance reports

Technical advantages:

-Permanent protection of wind turbines

-Detailed diagnosis of rotor, gearbox, generator and other parts

-Root cause analysis by documenting damage events

-Trend recording

-Spectrum recorder

-Different condition monitoring approaches used across the industry, including monitoring equipment and data analysis techniques

-Software developed with CM technologies best suited for your application

-Component level detail, including drive train, vibration monitoring

-Increasing the life of wind turbines through wind turbine CM techniques

-Using maintenance planning to reduce unscheduled maintenance and get more value from your assets through subsequent drops in downtime

-Methods for early indication of component failure and how repair work can be adapted depending on the failure

-Management of several turbines in a wind farm in

Vibration Monitoring:

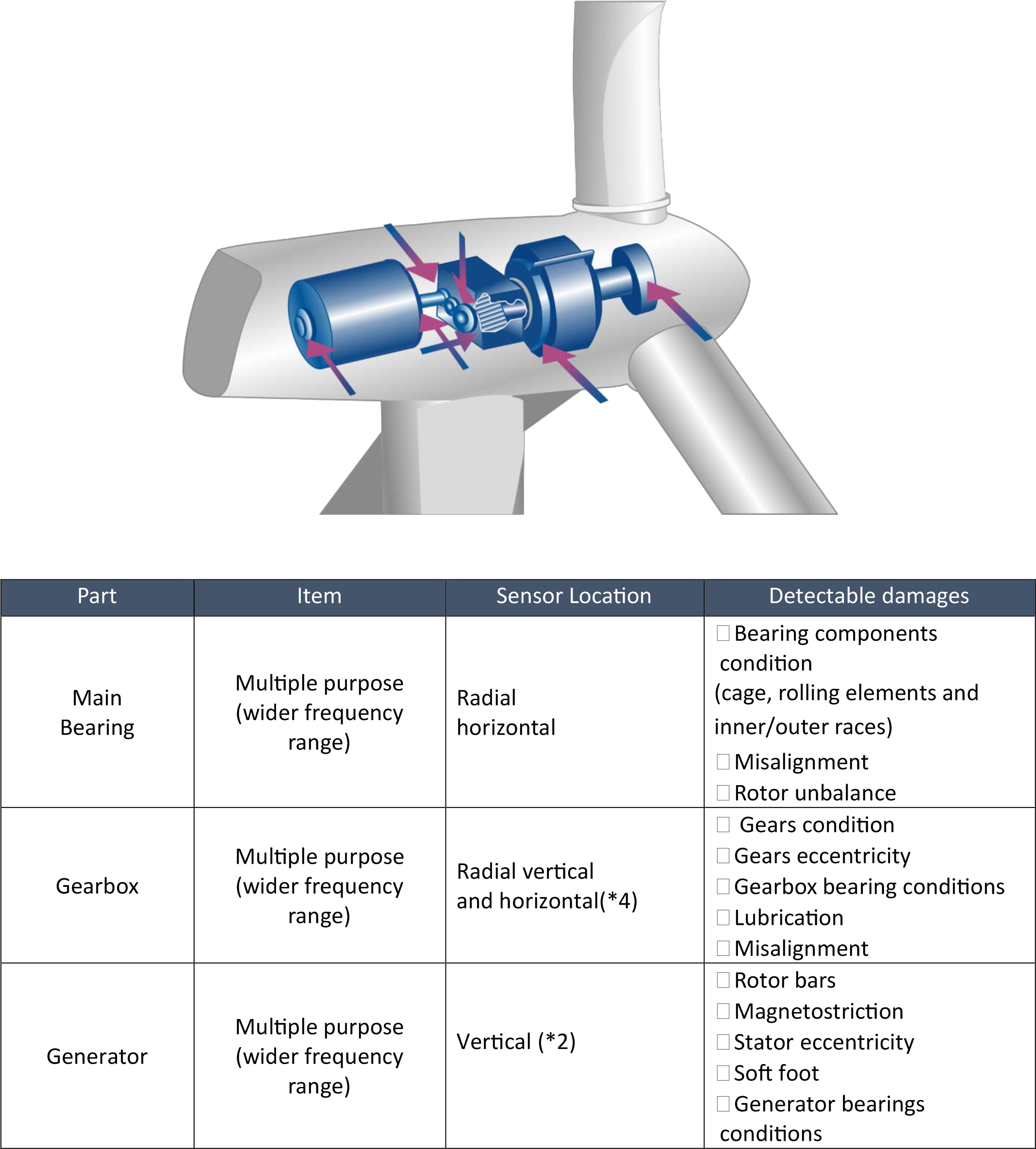

Vibration monitoring is one of the most important aspects in wind turbine monitoring because it helps to determine the condition of equipment. Wind turbine consists of turbine rotor, stator, bearings, gearbox and generator. Figure 1 show where vibration sensors are usually placed to read data in the axial and radial directions. Depending on the applicable frequency range, you can use either position sensors (low range), velocity sensors (mid-range), or accelerometers (high range) for this measurement. These vibration sensors are rigidly mounted to the component of interest and transmit an analog signal proportional to the instantaneous local motion. VibSens 4000 with high sampling rate, high dynamic range, and anti-aliasing filters is ideal for this type of measurement.

Vibration monitoring is one of the most important aspects in wind turbine monitoring because it helps to determine the condition of equipment. Wind turbine consists of turbine rotor, stator, bearings, gearbox and generator. Figure 1 show where vibration sensors are usually placed to read data in the axial and radial directions. Depending on the applicable frequency range, you can use either position sensors (low range), velocity sensors (mid-range), or accelerometers (high range) for this measurement. These vibration sensors are rigidly mounted to the component of interest and transmit an analog signal proportional to the instantaneous local motion. VibSens 4000 with high sampling rate, high dynamic range, and anti-aliasing filters is ideal for this type of measurement.