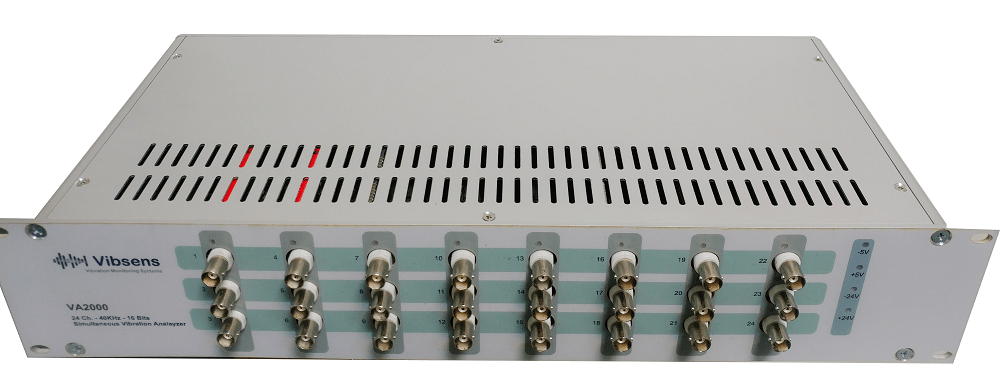

VA2000 is a condition monitoring system which can be used for multi-channel data acquisition, signal analysis and data processing.

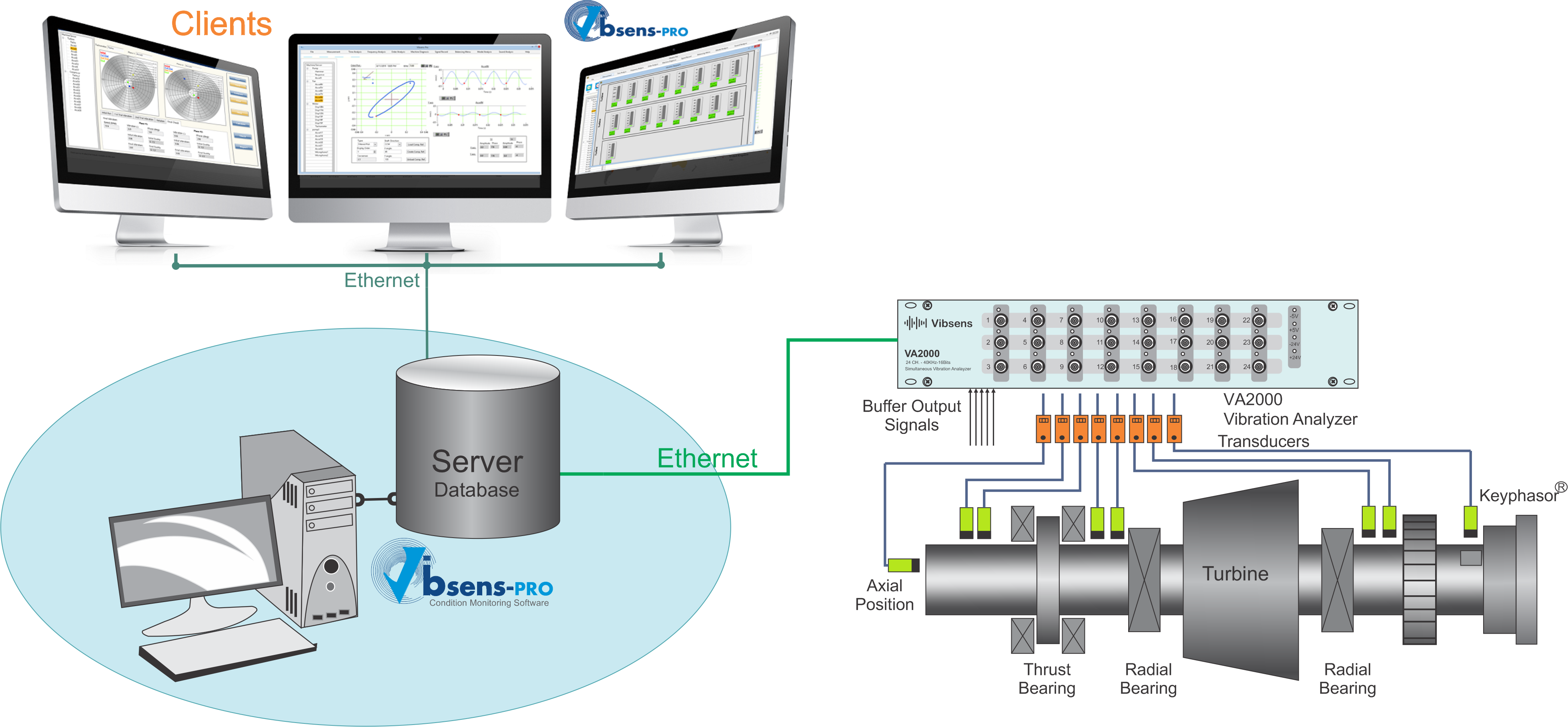

VA 2000 measurement system has been designed for on-line simultaneous data acquisition and presentation. It combines features of many instrumentation devices like oscilloscopes, filters, signal conditioners and data acquisition devices into a single device. Data communication with PC is performed by LAN/WAN network communication methods enabling users for easy remote operating of data processing and data storage. It can share data by a server to multiple clients over a network, if needed, enabling multiple users to perform signal analysis simultaneously on a machine. It has data storage ability and a specific software application for offline data review and analysis from historical data.

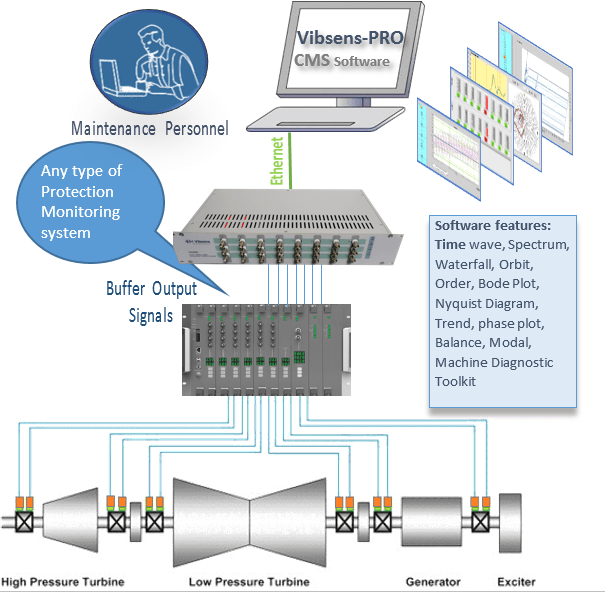

In this application, vibration transducers are installed on different points of the machine and connected to VA2000 through cabling and junction boxes. All the required processes for an on-line condition monitoring system are done and data is monitored to the user via a Industrial PC.

In this application, VA2000-Rack can be connected to the buffered output signals of other 3rd party vibration protection systems and use existing protection system transducers as inputs to VA2000 and perform all the required on-line vibration analysis to improve the existing system from protection monitoring to on-line condition monitoring system in a cost effective way. The layout for both situations is depicted below.

Inputs

Measurement channels : 24

Resolution : 16 bits

Dynamic range : Maximum 96 dB

Input range : ± 24 V dc

Input impedance : 220 kΩ

Status LEDs : IEPE / ±5 V dc/ ±24 V dc

Connector : BNC / Rear terminals (only available in rack mounted version)

AC measurement range

Gain 1/4 : ± 5000 mV Pk-Pk

Gain 1/2 : ± 2500 mV Pk-Pk

Gain 1 : ± 1250 mV Pk-Pk

Gain 2 : ± 625 mV Pk-Pk

Gain 5 : ± 250 mV Pk-Pk

Gain 10 : ±125 mV Pk-Pk

Power Supply

Supply voltage : 24 Vdc

Supply current : 250 mA

Ripple : 50 mV

Battery life : 6 hours

3 Channels : 40

6 Channels : 30

15 Channels : 20

24 Channels : 12

Maximum FFT Lines

3 Channels : 150000

6 Channels : 75000

15 Channels : 30000

24 Channels : 18000

Trigger

Free-run, hardware (Ch#1) & software trigger (Trigger time & level configurable via software)

Output generator

1 BNC output, Single Sine, Multi sine (phase configurable), Single step & continuous generation

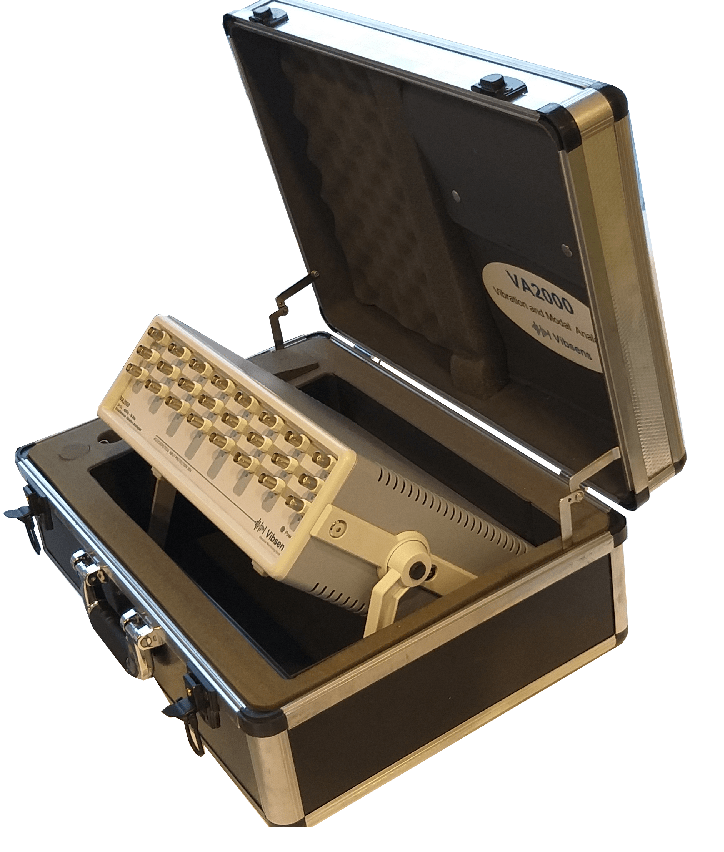

Portable : 115 * 260 *370

Temperature range : -5 to +65 °C

Supplied accessories : LAN cable, aluminum enclosure, power supply, battery charger

Weight (kg) : 3.3

Humidity : 90 % RH or less (no condensation)

-2014/30/EU EMC directive

-2014/35/EU low voltage directive

-EN 61326-1:2013

-EN 61010-1:2010

- Vibsens-PRO CMS Condition Monitoring Software

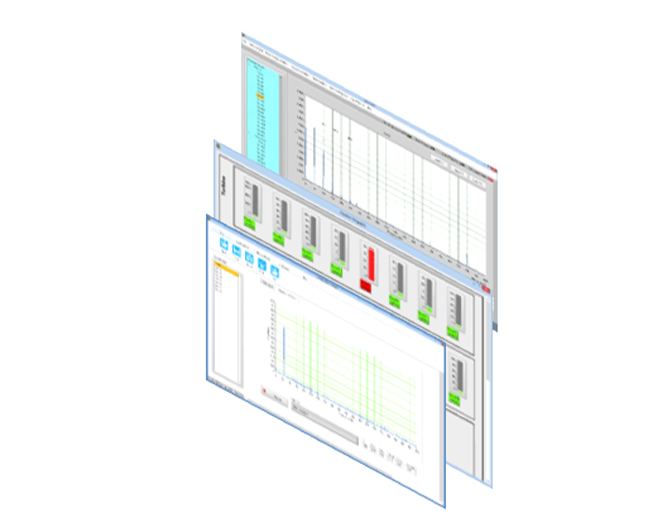

Vibsens-PRO is a machine condition monitoring software that collects, stores, analyzes and is capable of transmitting machine status monitoring information over local or wide area network. It provides static, dynamic and transient data collection and analysis; such as graphical indication of overall vibration values, vibration long time trend, signal waveform, frequency spectrum, orbit plot, polar plot, waterfall, bode plots, cascade plots and much more. Vibsens-PRO may be run on Microsoft Windows® platforms connecting to various Vibsens vibration protection systems.

Additionally, it collects process data via Modbus from 3rd party hardware and monitors and stores data for further data processing. With its reliability, it not only can acquire the data from third party but also share its data with third party software and hardware.

Vibsens-Pro can be used as a client running on a PC with network access to server computer and processing offline historic data. Several Vibsens-Pro samples may be ordered for multiple users either for maintenance department performing vibration analysis or a sample just used as a general trend monitoring system.

VA2000 Vibsens-PRO CMS Condition Monitoring Software Data sheet Download File